When designing a PAT testing system for the first time, it can be a huge task to draw up an inventory of items to be tested, particularly if you are part of a large organisation or have a large scope of responsibility. The good news is you only have to do this once, and after that you just add new items to the asset list, or remove items that have been thrown away. However, it is important that you understand what items should be included on a PAT testing list, so that you are fully compliant with the regulations, so that you are testing every item that poses a safety risk and so that you are not wasting time testing items you don’t need to.

A definition of items that require PAT testing

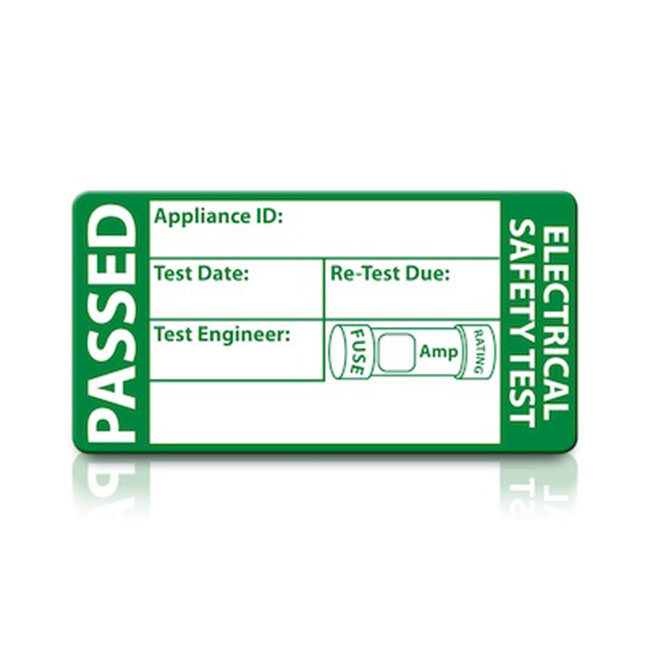

The general definition for items that require PAT testing is anything that has a flexible cable and which therefore plugs into a power source, usually a plug socket. Therefore, any appliance that has a plug and that is connected to mains electricity via a wall socket or generator, needs to be PAT tested.

So in a typical commercial office, this would include laptops, PCs, monitors, photocopiers and printers. In the communal kitchen of a commercial business or a rented property, this could include kettles, fridges, microwaves and toasters. In a maintenance department this could include hand drills, hand grinders and hand sanders, plus other power tools used and items such as vacuum cleaners.

However, that doesn’t mean that everything needs to be portable, and that is where the term ‘Portable Appliance Testing’ can be a little misleading. You would not consider some items in the kitchen or canteen of a commercial business to be portable, for example, such as a refrigerator or a vending machine. Likewise, in a residential home that a landlord is renting out, this would include integrated dishwashers, an electric oven and hob or a fridge/freezer. However, because all these items are plugged into a wall socket, they are classed as ‘portable’ and therefore should be tested under the PAT testing regime.

Considerations when identifying appliances that need PAT testing

There are a number of common queries and anomalies when it comes to identifying items to be PAT tested, and which require separate discussion. These include:

- Cordless items – Any item that runs on batteries, such as a cordless screwdriver, does not need to be PAT tested, but the associated battery charger that connects to the mains wall socket DOES need to be tested.

- Power sources – Equally, where a laptop has a separate power source that can be detached, this is classed as two separate items because the laptop and the power pack are held to different electrical standards. So the laptop and the power source should be tested separately in this case.

- Disposable batteries – Anything that runs off disposable batteries, such as a wireless keyboard or mouse, does not need to be PAT tested.

- Fixed appliances – Some fixed appliances are integrated or hard-wired into the mains source, such as heated towel rails or storage heaters, these still need to be PAT tested because they are connected to the mains source, albeit not via a regular plug socket.

- New items – As long as a new electrical item is purchased from a reputable supplier or manufacturer, and is not damaged, it does not need to be PAT tested upon receipt, as it should be sold in good working order. However, as soon as it is used, the item should be risk-assessed and added to the appropriate section of the PAT testing inventory, so that it is tested on the next appropriate frequency round.

How often should I test my electrical items?

All electrical items on your PAT testing asset list will have different variables in terms of what they are used for, how they are used, who uses them, where they are used and where they are stored. These factors can vary quite considerably in terms of harsh environments, frequency of use and what operations they are used for. So a comprehensive risk assessment of each item is required to establish what safety risks the item is exposed to, and therefore how often it should be tested. For example, you would test a power drill that is used all day every day in a heavy duty manufacturing environment more frequently than a lamp that is situated on a shelf in the MD’s office.

In most cases common sense can be applied, but this frequency can be monitored and addressed where safety issues arise, or where any of these variable factors change.

Video Demonstration

Test Instrument Solutions offeres a quality range of pat testing equipment such as the TIS 700, which can be seen in the product demonstration video below:

Please note that this section is for information purposes only. Anyone using equipment referred to in this section must be suitably qualified and/or experienced within the respective field. If in doubt before use, please consult a qualified electrician or engineer & thoroughly read all instruction booklets.